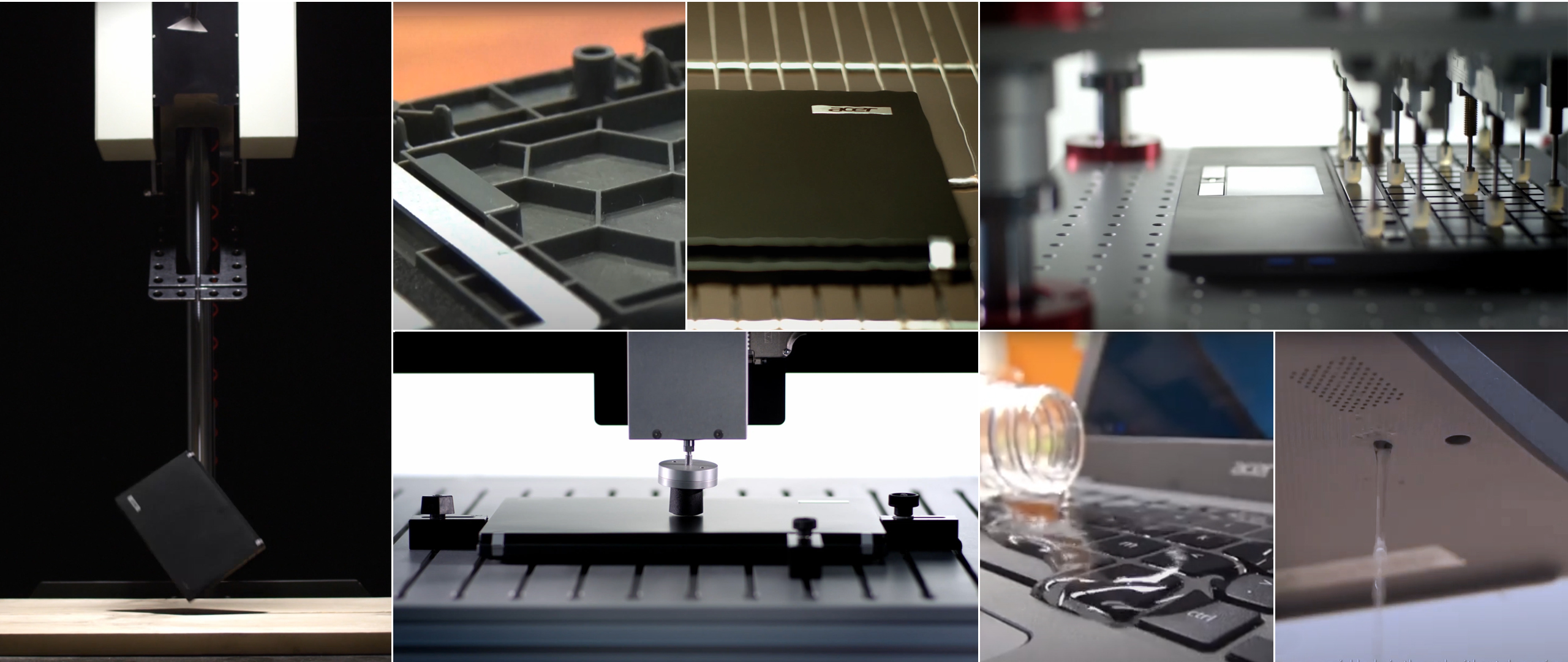

Military Grade Reliability

Acer’s commitment to your business begins before you open the package. By testing our products to MIL-STD-810H standards and Ingress Protection against water and dust you can be assured that your product will withstand more than you throw at it on an average day in the classroom, warehouse or on site.

MIL-STD-810H Standards

The following items are the tests that devices bearing the MIL-STD-810H label have passed.

PREDATOR TRITON NEO 16 – GAMING LAPTOP

High and Low Temperatures Tests3

Humidity Test

Vibration Test

Drop Test

Rain Test

Dust Test

ENDURO - Ruggedized Devices

High and Low Temperatures1

Rain

Humidity

Vibration Test1

Drop Test1

Sand and Dust2

Low Pressure (Altitude) Testing2

Salt Fog2

Temperature Shock2

TravelMate - Business Laptops

High and Low Temperatures

Rain

Humidity

Vibration Test

Drop Test

Shock Test2

Chromebook - Work and Study

High and Low Temperatures

Rain

Humidity

Vibration Test

Drop Test

Sand and Dust2

High Temperature Operating2

Shock Test2

Low Pressure (Altitude) Testing2

Solar Radiation (Sunshine)2

Veriton - Commercial PCs

High and Low Temperatures

Humidity

Vibration Test

Drop Test

Sand and Dust2

ENDURO Urban – Stylish Durability

Drop Test

Vibration Test

Sand and Dust2

Humidity2

High and Low Temperatures1

Low Pressure (Altitude) Testing2

Recommended for You

IP Testing

Ingress Protection testing is separate to MIL-STD-810H and offers a guarantee as to how much dust and liquid the device will withstand. It is published by the International Electrotechnical Commission (IEC). The equivalent European standard is EN 60529.

The first number represents the amount of solids that can enter, and the second number represents the amount of protection from moisture such as drips, sprays, submersion etc. The table below explains what each number means. For example IP 68 is fully resistant to dust and submersion in water for long periods.

Protected against solid objects over 50mm (1.96”) in diameter e.g. hands, large tools.

Protected against solid objects not over 80mm (3.14) in length and 12 mm in diameter.

Protected against solid objects over 2.5mm (0.09”) e.g. wire, small tools.

Protected against solid objects over 1mm (0.04”) e.g. wires.

Partial protection against dust that may harm equipment.

Totally protected against dust ingress including a vacuum seal, tested against continuous airflow.

Protected against vertically falling drops of water or condensation.

Protected against falling drops of water, deflected up to 15°from vertical.

Protected against sprays of water from any direction, even if the case is deflected up to 60° from vertical.

Protected against splash water from any direction for a minimum of 10 minutes.

Protected against low pressure water jets (6.3mm (0.24”)) from any direction. Limited ingress permitted.

Protected against high pressure water jets from any direction. Limited ingress permitted.

Protected against the effects of immersion in water between 15cm (5.90”) and 1 meter (39.37”) for 30 minutes.

Protected against the effects of immersion in water under pressure for long periods.

2 Tested on specific models only. See individual product pages for details.

3 Consisted of four different tests:

High Temperature Test I, Low Temperature Test I: 48 hours Non-Operating

High Temperature Test II, Low Temperature Test II: 8 hours Operating